DF400

Metal Power Line

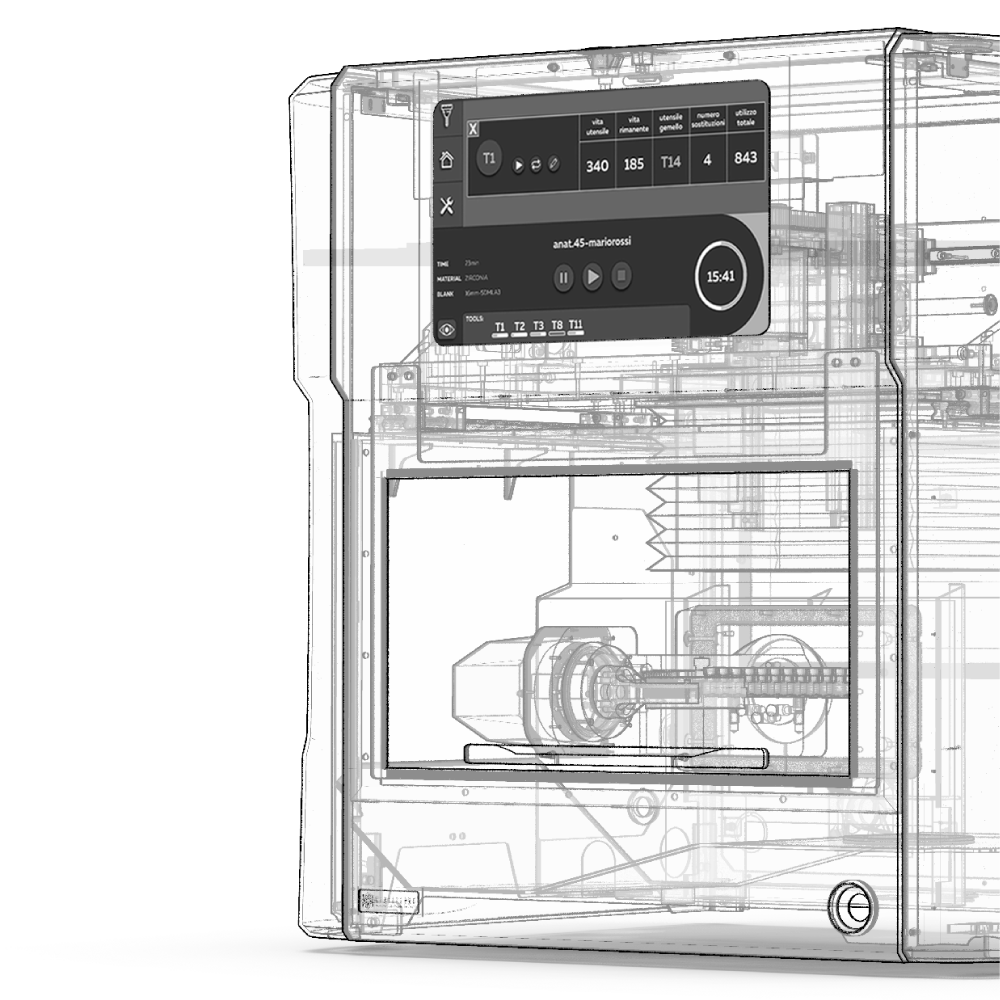

A compact and highly rigid mechanics, together with the electronics and high-quality components, provides a precision and speed never experienced before.

The extended inclinations of axes allow to perform machining with important misalignment.

The heavy industry concept of the machine allows you to deal with large volumes with maximum reliability.

The high power of the 3.2 kW electrospindle allows the use of specific tools for metal, which provide extremely reduced processing times and astonishing finishing level.

The working area – built as a single block with the chassis – provides an unlimited life to the dust seal and simplifies the cleaning operation.

DF400 technical features

Monocoque chassis

High rigidity steel structure, electro-welded and precision machined.

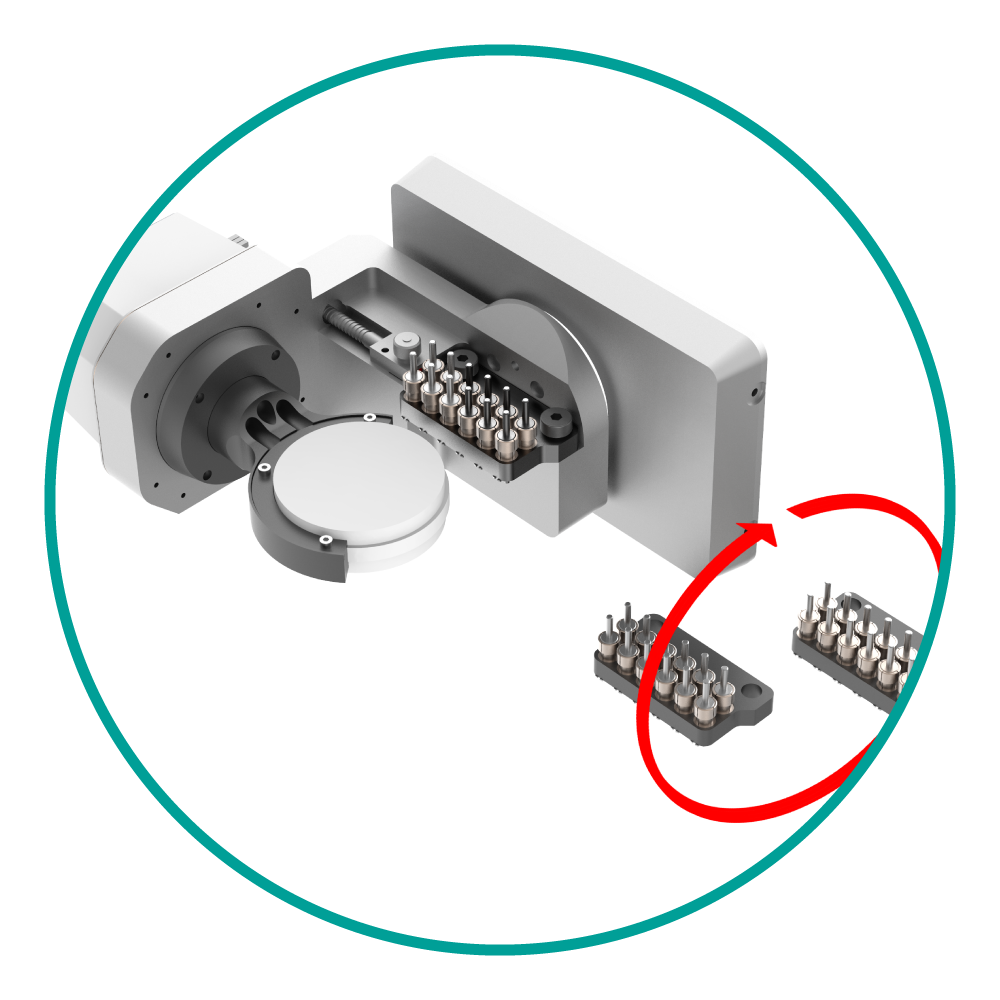

Quick change of tool set

In case of change of material, it is possible to quickly replace the whole tool support instead of the single tools.

Aspiration and lubrication

The suction nozzle works synchronously with the air blowing system; the nozzle is ready for fitting the lubrication system (optional).

Lubrication system

The innovative filtering system keeps the lubrication liquid always clean and ready for use. Level can be checked both visually and electronically.

Optional disponibili

Quick disc change (manual)

A special precision attachment (manually operated) allows the disc holder to be replaced in a few seconds to stop a job – to advance an urgent one – and to resume it later.

Support table with accessories

Any Dental Four milling machine can be equipped with its support table, specifically designed to include – in a practical and highly functional way – the filtering and lubrication system, the cooling system and the suction unit.

Our Cad-Cam technology by your side

Dental Four is a innovative start up, independent from material and tool producers, established by technicians with more than 10 years of experience in dental Cad-Cam.

Dental Four designs and manufactures dental milling machines suitable for all dental labs, thanks to their precision and flexibility.

Its milling machines are highly innovative, since are designed, manufactured and maintained according to the most advanced criteria of environmental sustainability.

Dental Four’s mission is simple: fill the gap between the products and the user; it provides in-depth training and immediate technical assistance.

Dental Four is based in Bobbio (Piacenza, Italy), in the mechatronics district, renowned for the production of precision mechanical components for numerically controlled machine tools.

Support table with accessories

Optional

Any Dental Four milling machine can be equipped with its support table, specifically designed to include – in a practical and highly functional way – the filtering and lubrication system, the cooling system and the suction unit.

To speed up the cleaning operations, the table is equipped with caster wheels with support foot.

Because of the rational arrangement of the included accessories, the ease of cleaning and the elegance of its design, this table is the perfect completion of your milling machine.

Filtration system

Optional

The filter system is designed for all materials used in dental labs. Due to its variety, it combines the effect of 4 filters and 2 settling tanks.

The coarse chips are collected in the top BASKET and filtered by a first removable PAPER FILTER (pre-cut and supplied as a spare); the liquid, already partially filtered, enters the DECANTING TANK, then goes through the SPONGE FILTERS and finally flows into the TANK of 25 liters of capacity.

The tank is equipped with a visual level indicator (electronically duplicated on the main display), low level sensor and drain discharge valve located about 30 cm above the ground.